Infrastructure

| NAME OF THE LABORATORY | NUMERS IN TOTAL | Pharmaceutics and Microbiology Lab | 04 |

|---|---|

| Pharmaceutical Chemistry/Analysis Lab0 | 04 |

| Pharmacology Lab - UG | 03 |

| Pharmacognosy Lab | 02 |

| Pharmacy Practice Lab | 02 |

| Pharmacology Lab - PG | 02 |

| Pathophysiology | 01 |

| Central Instrumentation Lab | 01 |

| Machine Room | 01 |

| Computer Lab | 01 |

Total Number of Lecture Halls – 07

Total Number of Labs – 21

Faculty of Pharmacy possesses all the desired equipment’s prescribed by various regulatory bodies each laboratory is provided with firefighting equipment, emergency shower and first-aid box for safety. State-of-the art thirteen laboratories, Machine Room and Computer lab help students to practically learn the theoretical concepts and also the skill of working with sophisticated equipments.

Faculty of Pharmacy has five departments viz., Pharmaceutical & Medicinal Chemistry, Pharmaceutics, Pharmacology, Pharmacy Practice and Pharmacognosy.

1.THE DEPARTMENT OF PHARMACEUTICS labs include Pharmaceutics-I, Pharmaceutics-II and Microbiology lab and Machine room. In addition, there is a separate in-process quality control room. GMP standards are implemented in the design of the labs including concealed water and sewage lines, microscope lights, balance covers and provision of adequate lockers. There is a separate preparation area in each lab.

Practical’s dealing with sterile operations are conducted in Microbiology Lab. This lab has an excellently designed sterile area with wash and change areas, air locks, air shower, laminar bench and HEPA filters. We have an integrated and well-designed Machine Room which has many equipment and machines for dosage form development including solids, coating, liquids, semisolids and size reduction mills.

THE DEPARTMENT OF PHARMACY PRACTICE experiences to help the students to prepare for their rotations and future careers in the healthcare field. The system allows any student in the lab to input and verify prescriptions, adverse drug reactions, drug interactions in real-time under the supervision of a teaching assistant or instructor.

Central Facilities in the Department

Machine Room

Mini Press (MODEL :LAB PRESS 1)

In the tablet compression machine main principle is compressing the grains/powder in upper and lower punch in a die hole. The hydraulic pressure plays a key role. This pressure is transmitted unreduced through the static fluid. Any externally applied pressure is transmitted via static fluid to all the direction in same proportion. It also makes it possible to multiply the force as needed. If we increase the hydraulic pressure more compressing force on tablet then it becomes harder.

Lab Press is a High Tech Rotary Tablet Press in table-top design for R&D and small batch production. This Single sided R&D Tablet Press fully conforms to GMP and the safety requirements. All Electrical settings can be performed by Front panel with indicators at the front of the machine. The turret is driven by centre shaft drive mechanism by a motor and Powerful Reduction gear box. The Tablet output depends upon the properties, tablet shape, weight, thickness as well as quality of granules of material to be compress.

This machine is designed for pressing tablets from a variety of materials for Research and Development and for small-scale production of Neutraceuticals,herbals, and other products. It is designed for pressing round tablets from various granular materials.

All Purpose Unit

All-purpose unit comprises of a vertical main drive to which various attachments can be connected to carryout different operations.

Vertical Drive

The Universal Gear

Coating Pan

The Coating pan is used to produce uniform coating on tablets with the help of Baffles inside of pan. This can be mounting on the universal gearing and as a result different tilting angle can be set up to 45 Degree.It is also permits speed control at any desired RPM. The pan capacity is 9.5 Liters

Polishing Drum

Double Cone Mixer

Planetary Mixer

Humidity Chamber

R4 Centrifuge

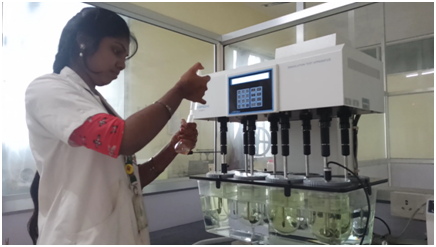

Dissolution Tester (MODEL: DS 8000 BASIC)

Salient Features

- The equipment complies with current USP , IP ,BP, & EP and ASTM specifications.

- External vibration free Water Circulator for uniform water circulation with audible and low water level alarm.

- Mono shaft design with automatic adjustment for 25 mm depth setting with easy changeover between Apparatus I & II eliminates routine height validation as per USP.

- Paddles, Baskets and Vessels are laser marked with serial numbers for traceability.

- Tablet dispenser (Optional) drops 6 dosage form at single instance.

- The conical shape low evaporation recovery lids reduces media loss during long run.

- Facility to monitor Vessel temp, with DTS Technology (Digital Temperature Sensor)

TRAY DRYER: (K LAB)